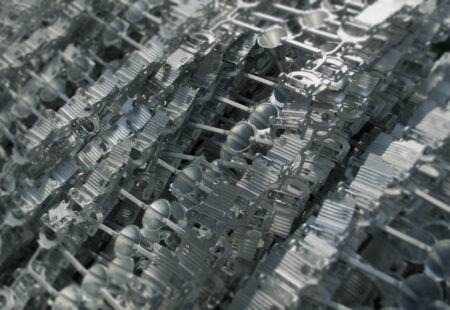

Our aluminum and zamak foundry is a team of young, highly qualified employees to whom the company owes its prestige and the highest quality of services and products offered. The team works in a three-shift system, which guarantees the timely delivery of services and orders.

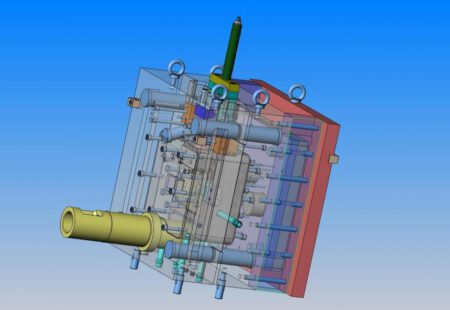

As a technologically advanced foundry, we focus on the highest quality, which is why we use the advice of the Foundry Institute in Cracow and the services of recognized designers and mold contractors in Małopolska. The foundry works according to rules: from design to mass production. We are available to our clients both in terms of production (pressure casting, machining, powder coating, electroplating, assembly, packaging) and technical consulting (selection of materials, design elements, mold design, mold making).

In order to meet these needs, the GALJA pressure foundry is systematically extending the scope of its services, e.g. in 2006 a powder coating shop was opened. Experience, flexibility and timely execution of orders make us a reliable business partner.

We invite both small entrepreneurs and large companies to cooperate with us!